PRODUCTS

Vacuum forming

Design, prototype

manufacturing

and sales

Prototypes will be made in Japan, mass production will be done in Thailand and Vietnam.

Please feel free to contact us with any questions you may have, such as requests for prototype production or product planning and development.

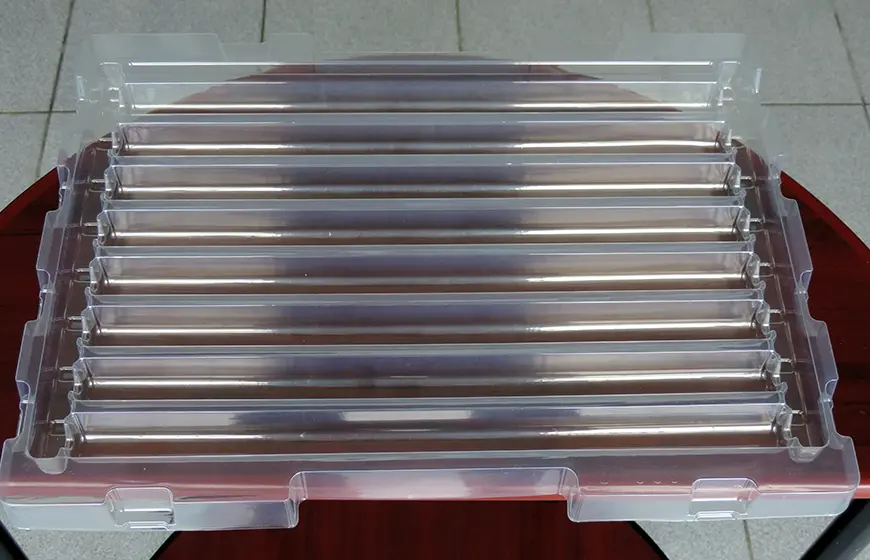

Blister pack

/ Parts transport tray

Since it is mass-produced overseas, if the prototype is also shipped overseas, sample transportation costs and time will be required. Why not cut that waste?

We manufacture everything from design to sample to mass production at our partner factories. We also have partner factories overseas (Thailand and Vietnam), so we can handle mass production there as well.

Materials handled

- A-PET t=0.25~1.2mm Chargeable and conductive compatible

- PS t=0.35~1.5mm Chargeable and conductive compatible

- PP t=0.35~1.5mm Can handle charging

Taking advantage of our strength as a trading company specializing in chemicals, we are able to obtain materials in small lots at low prices.

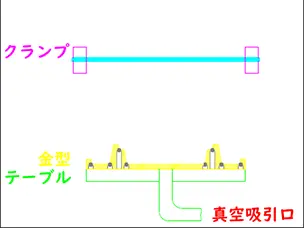

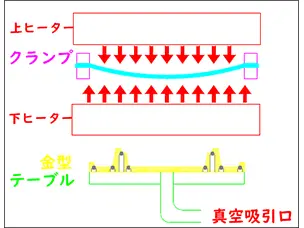

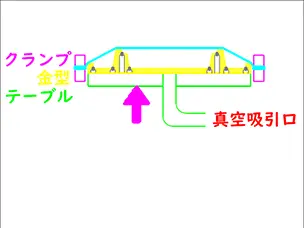

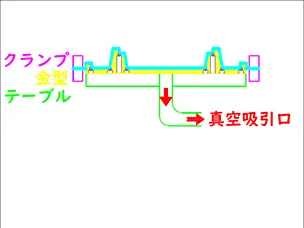

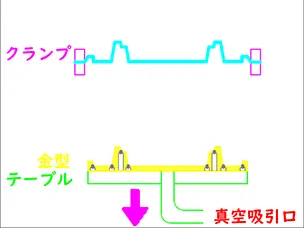

Vacuum forming manufacturing method

(1) Material set

(2) Material heating, softening

(3) Table up

(4) Create a vacuum inside the mold and use the pressure difference to tightly adhere the softened sheet to the mold

(5) Cool and release the mold to complete the molding

Contact us for more details

Inquiry form

Inquiry form